There are many ways to build a loudspeaker cabinet. Most are rectangular, some are more interesting shapes. The majority are made of wood and a few of concrete. One famous example was made of ceramic.

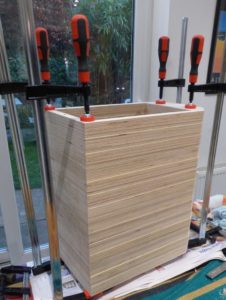

Cabinet design is an area which is always subject to a manufacturer/designer’s own particular philosophy. One of the most interesting is trans-lamination (or translam) as used by manufacturers such as TAD for their upmarket designs. It consists of taking a sheet of material (such as ply or MDF) and cutting out shapes which when stacked (usually vertically) form the completed cabinet. The exterior can be shaped and the interior of the cabinet is formed by the hole in the centre of the successive slices.

A fine example is the Eikona TL3 translam enclosure built by Ian, our Gloucestershire-based demonstrator. In an email Q&A, we asked him to share some details.

What made you decide to try this?

I’ve liked the look of translam cabinets for quite some time not least because, for an amateur builder, it gives a relatively simple method of getting away from a rectangular box.

Any specific difficulties encountered?

No real difficulties as I had the slices cut by CNC. The holes drilled at the time made for easy location of each slice using dowels in the holes. Probably the hardest part was fitting the internal divider although once I’d figured it out it was quite simple to do.

What would you change if you did it again?

I’m not sure I would change anything but I did consider putting a layer of MDF over the baffle in order to recess the drivers. Cutting the holes was straightforward using a hole saw but I decided not to risk routing the rebate as I suspect the ply edge would have torn. In any case I’m happy with the looks and performance.

What were the overall benefits?

I did make up a standard cabinet using MDF to test the design so I do have a handle on the differences a translam build provided. OK, I’m comparing MDF and ply as well as the construction method but the translam cabinets feel a lot more solid and, more importantly, the sound more solid! I think the extra stiffness of the cabinets has reduced colouration a little so that micro-detail is easier to hear, which gives a greater sense of space. That’s not to say that the standard box cabinet does not produce a very fine-sounding speaker.

A fellow audiophile commented:

“All I can say is that Ian’s dual Jordan speakers are incredible.

I appreciate what full range drivers can do, with no smearing of phase response due to cross-over effects. I have heard Ian’s 4 speaker units before but these sound more balanced and don’t suffer from any lack of bass extension. The translam construction is so inert as to be completely out of the picture regarding any cabinet resonance. There is a fantastic immediacy to the sound which is totally beguiling.”

The CNC cutting was done by CKJ in Stroud, who generously made their CNC files available. These, along with Ian’s original drawings, are available to download as a ZIP file here.

Read the Eikona TL3 blog for plans and background to the design.