We recently received photographs of an extraordinary enclosure for the Jordan Eikona 2, sent to us by Bruce at Ars Harmonia, our USA distributor. Along with them came an enthusiastic description by Paul, the constructor:

“The Eikona 2s are an improvement over the JX92S, more open, cleaner and warmer sounding. The highs are just great and they lack the breakup that made the JX92S overly aggressive on some music. Of course the bass kicks butt. I ran them for a week in their boxes before installing to break them in, time will tell if they will continue to break in with use. One of my worries was their efficiency, I can tell no difference in efficiency and the JX92S. I’m driving them with a class A amp (DIY Pass Sony VFET) with power to spare. I’ve attached a few pics that you can use and send to EJJ. After a week or so of listening I’ll post my impressions over on the DIYAUDIO fullrange forum, as there was a bit of interest about these drivers.”

This got us intrigued and we had to know more. Paul kindly offered to write up his thinking behind the enclosure and his construction method. A point to note is how clearly Paul set out his aims with this project, before even beginning the computer simulations, let alone starting to build.

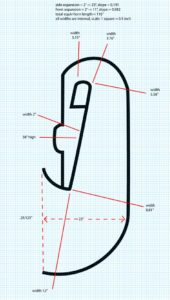

Note that the plan shown is a sketch and is all we have. A higher resolution is available from us (email for a copy). Click on any of the images for a larger version.

Over to Paul:

Quite a while ago I started building my own speakers using readily available designs, I made a few sets of two and three ways which turned out really well, and eventually began experimenting with full-range speakers. As luck would have it just around this time Martin J King had just made the first versions of his famous Mathcad spreadsheets available to the public. I decided that I would try and build a set of horn speakers since I had heard so much hype about them. I ran about a million simulations with Martin’s spreadsheets, and what I found was that a straight horn modelled much better than an exponential, or hyperbolic horn, and that a large chamber for the speaker really improved the response. I used the specs for the Jordan JX92S for my sims.

My criteria were: A decent off-axis response, true full-range frequency response, not too humongous in size, and it had to be built using hand tools because that is all I had. I wanted the horn to expand along two axis, not just one as in most of the horn designs that I’d seen. I added a diffraction ring made out of solid maple to help with diffraction effects, to move the driver closer to the horn mouth, and because it looked cool. The driver is set 38” off the floor which is about my ear height when seated. I also wanted a front facing mouth that would couple with the floor to make the room part of the horn. I lined the inside of the horn mouth with carpet that looked like felt, and braced it with oak dowels to keep it from resonating.

Warning: this was a challenging build, much harder than a simple box.

With the JX92S I needed to stuff the upper part of the horn body with polyfill to tune the bass response, and I needed to add a baffle step filter. My filter ended up being a 1.5mH foil inductor with 6 ohm resistor bypassed by a 0.5 uF cap to help lift the upper end.

I used a compared a Radio Shack SPL meter and frequency response disk to measure the in-room response from my listening position, and repeated the same measurements using my 3-way speakers. (Sorry folks, that’s all I had at the time.) The response after tuning was very close to the 3-ways, flat and extended into the high frequencies. The in-room bass response was much deeper than the sims indicated; the early Mathcad models didn’t account for room effects. As a result, I measured output down into the 20’s. These speakers have deeper, more punchy bass than my 10” bass driver, 3-ways.

MOVING TO THE EIKONA 2

I lived with the JX92S in these horns and enjoyed them for 13 years, they are very impressive for such small drivers. But they did have their warts; the upper mids and lower treble can sound harsh on certain recordings and nothing that I tried over the years could change that. After hearing good things about the Eikona 2’s I decided to take a gamble and try a pair out in the horns. Their T&S parameters are pretty close. I dropped them right in with no adjustments. I’ve had a couple of months now to evaluate them and they are a worthy upgrade, better in every respect than the JX92S. They have greater detail, better bass response, smoother mid/upper end response, and gone is the harshness that the JX92S could show.

I’m driving the speakers with a 15 wpc class A amp with no problems, they get way louder than I can stand. They are the most transparent/holographic speakers that I have. My 3-ways ,although they sound great, seem veiled in comparison. All-in-all I am very impressed with the Eikona 2s. I don’t know how they sound in other enclosures, but they do sound great in these horns.

CONSTRUCTION

Here is the scale drawing that I used for the construction. One square on the graph paper equals ½”. Sorry that this is not the clearest, but it’s all I have. The horn throat is 2” x 2”, the mouth is 12” x 28 ½”, the horn path is 116” from the bottom of the mouth to throat. The horn is a linear expansion for most of its length and flares out only near the mouth. The speaker chamber was optimized for the Jordan JX92S.

The sides were made using ½” plywood, curf cuts were used near the mouth where it flared out to help with flexibility. I carefully drew the layout on one side and cut it out with a hand-held saber saw, then used the cut out as a template for the remaining three sides.

Here is a close up shot of the curf cuts, I used a circular saw to cut them by hand. The curf cuts were filled with construction adhesive using a putty knife to add strength and deadening.

Here is a pic of the first layer of plywood being applied to form the horn body. Note the temporary spacer sticks used to control the expansion, they were removed once the first skin was on the front/back and the shape was stable.

Here is a pic of the completed horn bodies, I built the speaker chambers separately and attached them (sorry I don’t have any pics of that part). The sides have a ¼” sheet of underlayment laminated on using construction adhesive, the back is composed of 3 sheets of underlayment laminated together using construction adhesive. The front only has two layers of underlayment laminated because the tight curve was a challenge and the speaker chamber added extra support. The speaker chamber was made from ¾” plywood and was laminated to the front using construction adhesive and screws. I added oak dowels to strengthen the mouth and keep it from resonating. The speaker chamber was treated like a bass reflex box and was lined with convoluted foam, and some polyfill was added in the final tuning process. The entire horn was veneered with birch, finished with a couple coats of linseed oil to bring out the grain, then a bunch of coats of wipe-on polyurethane was added on top for strength. I used some moulding to finish off the mouth edge to hide the plywood end grain and for a finished look. I used two rubber feet under the front of the mouth and one leg in the rear to stand the horns on the floor.

(Note that later I tried adding some tweeters to try to tame the aggressiveness of the JX92S in the upper mids/lower treble, they ended up sounding better without the tweeter.)